Description

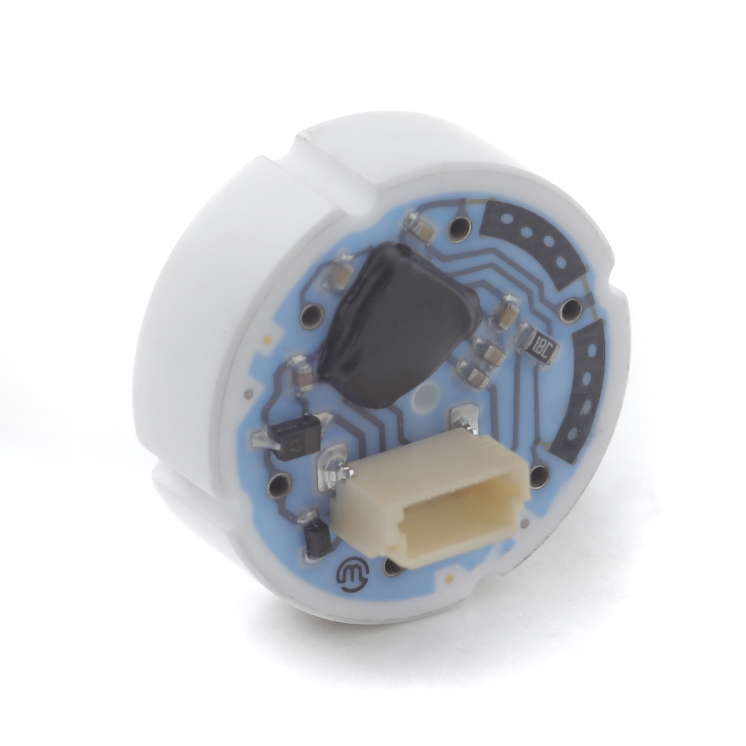

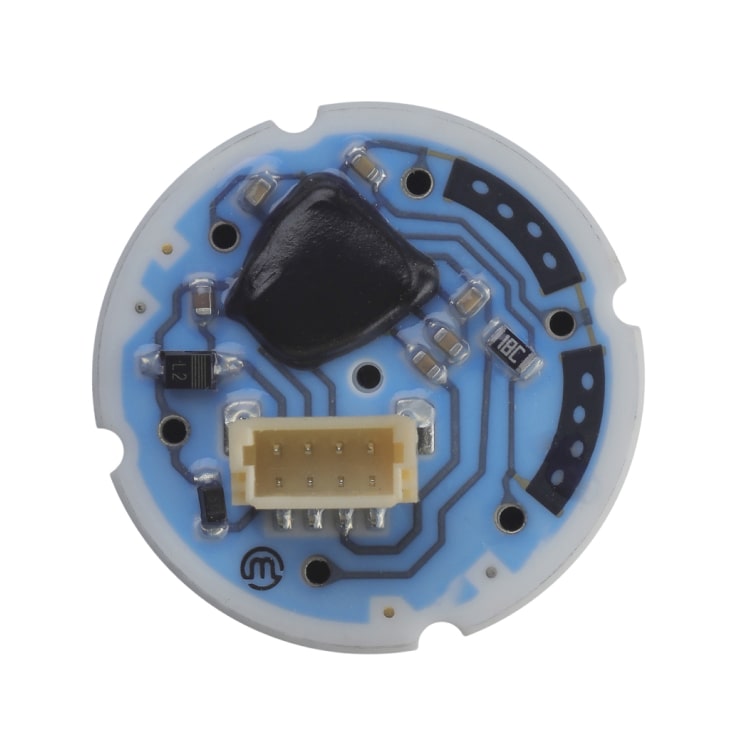

Metallux ME782 pressure sensors are made with a ceramic base plate and a flush diaphragm and they work following the piezoresistive principle. The Wheatstone bridge is screen printed on one side of the flush ceramic diaphragm, which is in turn glued to the sensor’s body.

The bridge faces the inside where a cavity is made. Signal conditioning electronics is directly integrated on the ceramic to generate I2C output with pressure and temperature information.

Calibration is done electronically with the onboard ASIC and it can be performed in bar (ME782) or in psi (MEP782). Electronics provides offset and span correction when the temperature changes. Zero correction software to compensate offset shift due to final customer assembly available on request. This allows good precision and long-term stability.

The Metallux ME782 family meets EMC requirements. The ASIC EEPROM stores

production lot specific data for sensor traceability and it allows custom calibration.

Due to the excellent chemical resistance of the Al2O3 ceramic, the ME782 sensors are

suitable for nearly all aggressive media.

Metallux ME782 are patented sensors.