Divisions

HYBRID

CIRCUITS

CIRCUITS

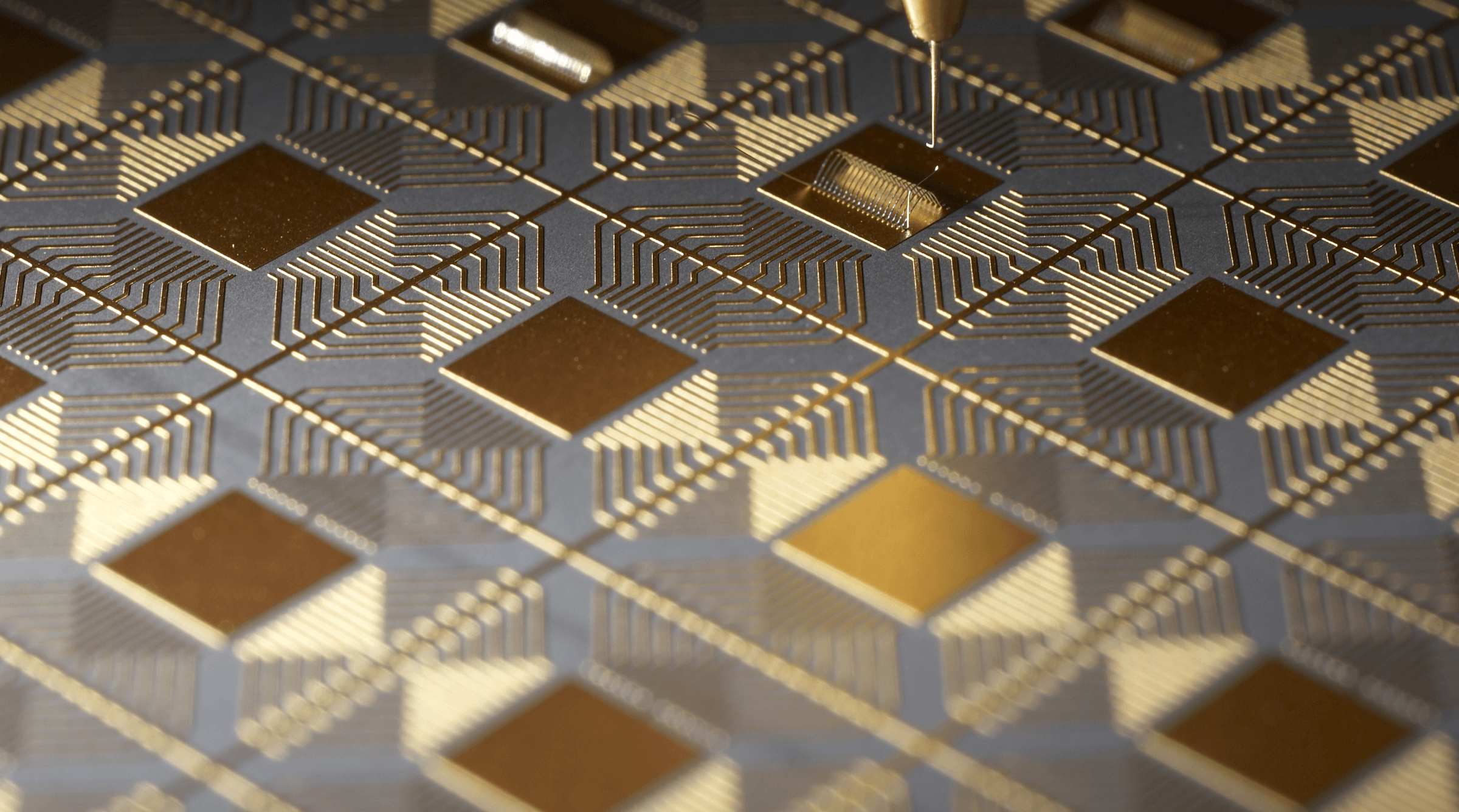

Metallux has a long experience in manufacturing multilayer hybrid

circuits, PCBA and microelectronics based on thick film technology.

Our know-how is a guarantee for maximum

reliability in the most demanding environmental conditions. Thick film

components are superior to conventional PCBs in terms of temperature

resistance and longevity.

01.

Thick film substrates

Metallux microelectronics is produced by means of thick film technology.

Conductive tracks, resistors, and insulating dielectrics are screen

printed and mounted in clean ISO 8 environment and then fired directly

to the substrate. Our flexible manufacturing is all about meeting

customer needs, a large variety of materials, such as: Ceramic Alumina,

Aluminium Nitride (AlN) or stainless steel and flexible PCB, allow the

manufacturing of your designed project up to the highest quality

standards.

Expertise and services

Metallux's Mendrisio site is specialized in the production of complex

substrates in thick film technology and in the assembly of

microelectronics on ceramics or PCBs. High quality electronics has been

produced for decades, serving the automotive, industrial, and medical

industries. The site's range of services include development, support,

technological product design, prototype construction, series production,

and qualification procedures.

Quality assurance stations for functional tests in series production are developed and set up from in-house engineering. Our approach ensures that even the most stringent quality requirements are met. The production site has 1,300 m² of clean rooms up to ISO class 7 (class 10000). Various encapsulation processes up to hermetic enclosures complete the capabilities of the production site.

Quality assurance stations for functional tests in series production are developed and set up from in-house engineering. Our approach ensures that even the most stringent quality requirements are met. The production site has 1,300 m² of clean rooms up to ISO class 7 (class 10000). Various encapsulation processes up to hermetic enclosures complete the capabilities of the production site.

02.

Electronic Manufacturing Services

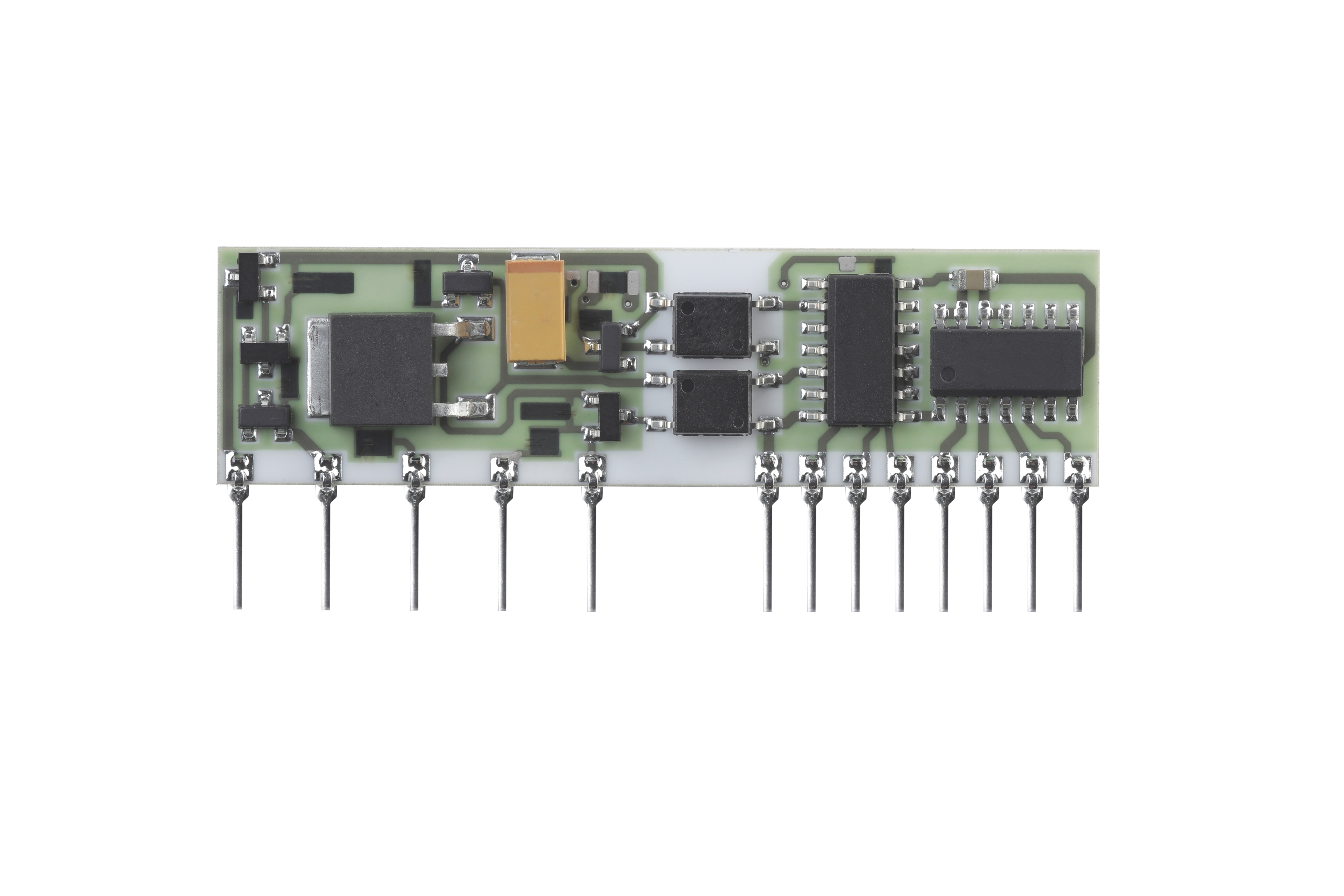

Metallux is an electronic service provider with a wide range of products

and manufacturing techniques in the field of printed circuit boards and

hybrid circuit assembly. Thanks to the expertise of its parent company

Eltek in the design and manufacturing of plastic and mechatronic

components, Metallux offers full-service solutions for the development

and production of electronic assemblies and devices, modules, or

complete systems.

Expertise and services

Our highly skilled and motivated engineering team uses the best and

brightest thinking to develope production processes for customers in the

field of the medical and industrial technologies. Our superior-quality

manufacturing process is certified according to ISO9001, ISO13485 and

IATF 16949. We aim to deliver high-quality, competitive, consistent

products focusing on research and development.

Metallux approach every client's unique project with an open toolbox and an open mind from the idea to the finished product. The first step of our approach is to analyze the application requirements and to define the target-cost with focus on design and performance.

Through advanced manufacturing and several testing methods, we are able to guarantee the production of high-quality reliable and durable Swiss made products. Component traceability turns quality assurance into quality insurance. Through advanced manufacturing and several testing methods, we are able to guarantee the production of high-quality reliable and durable Swiss made products. Component traceability turns quality assurance into quality insurance.

Metallux approach every client's unique project with an open toolbox and an open mind from the idea to the finished product. The first step of our approach is to analyze the application requirements and to define the target-cost with focus on design and performance.

Through advanced manufacturing and several testing methods, we are able to guarantee the production of high-quality reliable and durable Swiss made products. Component traceability turns quality assurance into quality insurance. Through advanced manufacturing and several testing methods, we are able to guarantee the production of high-quality reliable and durable Swiss made products. Component traceability turns quality assurance into quality insurance.

- Electronic layout

- Altium designer

- Electronic circuit projects

- 3D modelling of modules

- High density integration

VIEW MORE

Metallux is powered from technology and innovative thinking. Our

experties are: thick-film technology, screen-printing, population of

active and passive components, trimming and soldering processes,

bonding and the chip&wire technology.

03.

Electronic Manufacturing services

Metallux is specialized in the production of high-quality

customer-specific electronic modules. Our production covers small to

large series. Our corporate production structure -with locations in

Switzerland, Italy, Poland and China- allows innovation across our

tailored products and support mutual and sustainable growth.

Our production processes

Metallux's electronic production services include the following

production processes:

Assembly

- Laser marking / labelling of printed circuit boards with unique serial numbers

- Online tracking of production steps, component batches, and test data at assembly level

- Solder paste screen printing

- 2D solder paste inspection

- SMD assembly of printed circuit boards

- Reflow soldering

- Manual soldering according to IPC A-610

- Programming of integrated circuits

- Fully automatic coating and encapsulation of assemblies

- Assembly of prototypes, small series up to high-volume production

Inspection and Testing

- Automatic optical inspection (AOI)

- Functional testing

- Run-in/burn-in testing

- Cable testing

- X-ray inspection

- Assembly

- Checks and tests

Assembly

- Laser marking / labelling of printed circuit boards with unique serial numbers

- Online tracking of production steps, component batches, and test data at assembly level

- Solder paste screen printing

- 2D solder paste inspection

- SMD assembly of printed circuit boards

- Reflow soldering

- Manual soldering according to IPC A-610

- Programming of integrated circuits

- Fully automatic coating and encapsulation of assemblies

- Assembly of prototypes, small series up to high-volume production

Inspection and Testing

- Automatic optical inspection (AOI)

- Functional testing

- Run-in/burn-in testing

- Cable testing

- X-ray inspection

- Assembly

- Checks and tests

04.

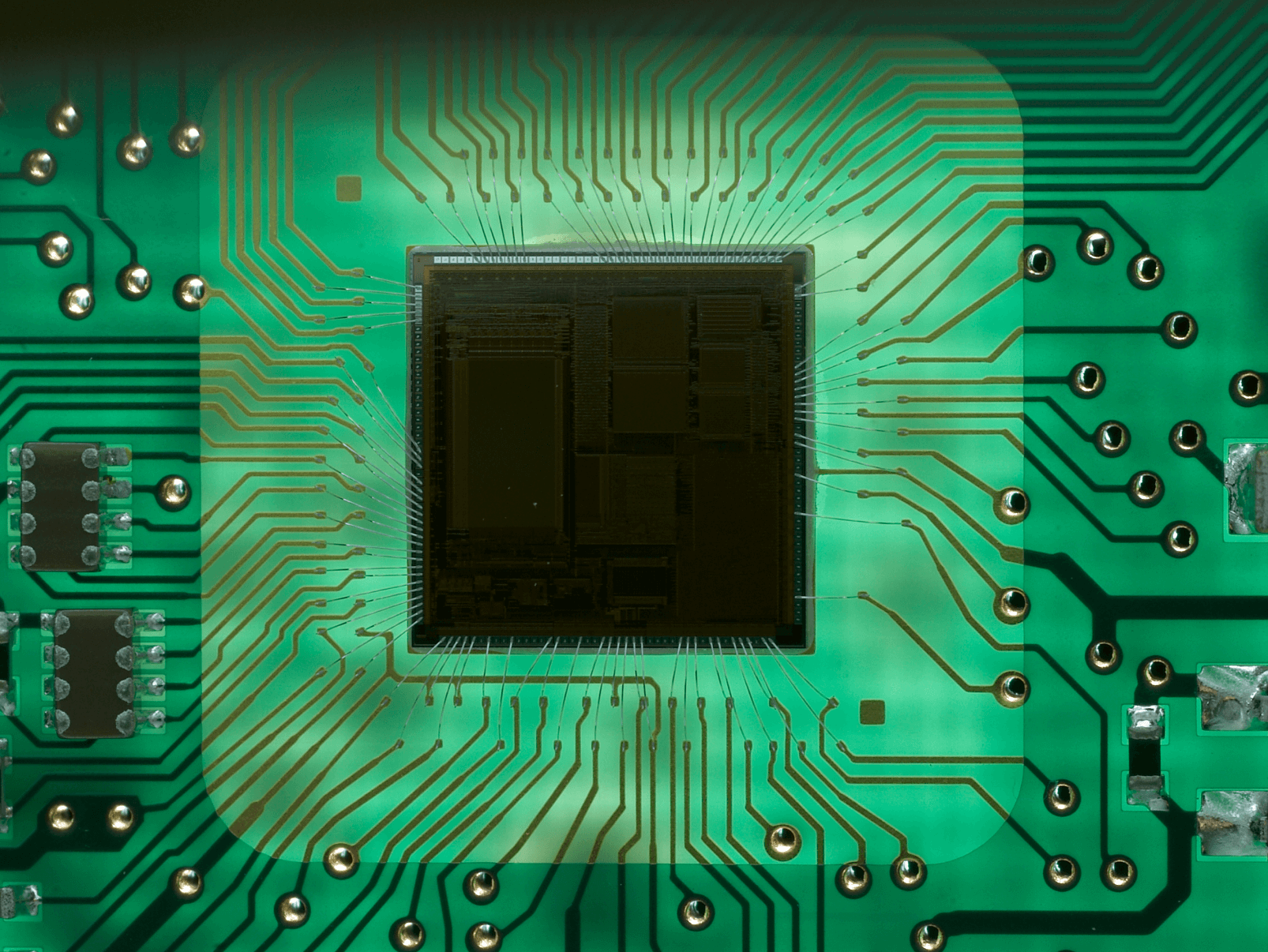

Microelectronic assembly

Metallux offers a broad portfolio of technologies for the production of

microelectronic modules and assemblies. Several production lines are

available for fully automated and semi-automated production.

Expertise and services

SMT Assembly of very small components from 01005 (0.2mm x 0.4mm) to

large BGAs of 40mm x 40mm with Chip & Wire technology.

Die Bonding

Metallux uses both bonding and soldering technologies for the assembly of bare chips in ISO 8 clean production. DNA- and RNA-free manufacturing is granted in ISO 7 clean rooms.

Wire Bonding

Metallux masters all bonding methods; wedge-wedge with Aluminium or Gold wire, wedge-wedge ribbon bonding with Aluminium or Gold ribbon, ball-stitch or ball-stitch on stud bump. The diameter of the wires used varies from 12.5µm to 50µm.

Encapsulation

A wide range of glob top materials is available, from epoxy to silicone or acrylic resins. Flip chips or micro BGA chips environmental protection is granted with underfill resins.

Screening, testing and qualification.

To ensure consistent quality and reliability, Metallux offers extensive testing and screening processes. Our consistency and processes are certified according to ISO 9001, ISO 13485 normatives.

Die Bonding

Metallux uses both bonding and soldering technologies for the assembly of bare chips in ISO 8 clean production. DNA- and RNA-free manufacturing is granted in ISO 7 clean rooms.

Wire Bonding

Metallux masters all bonding methods; wedge-wedge with Aluminium or Gold wire, wedge-wedge ribbon bonding with Aluminium or Gold ribbon, ball-stitch or ball-stitch on stud bump. The diameter of the wires used varies from 12.5µm to 50µm.

Encapsulation

A wide range of glob top materials is available, from epoxy to silicone or acrylic resins. Flip chips or micro BGA chips environmental protection is granted with underfill resins.

Screening, testing and qualification.

To ensure consistent quality and reliability, Metallux offers extensive testing and screening processes. Our consistency and processes are certified according to ISO 9001, ISO 13485 normatives.

- Engineering and test engineering

- Printed circuit board assembly

- Microelectronic assembly

- System assembly

Our industries

Doing good sits at the heart of everything we do. The Metallux logo is

a commitment to creating a better high-tech world for everyone by

unique opportunities to work with consumers to make sustainable living

commonplace. We partner with global OEMs, Tier 1, 2 & 3 through to

small family-owned stores, to grow our business and theirs.